Advanced Fasteners and Machining Techniques for Personalized Manufacturing

Advanced Fasteners and Machining Techniques for Personalized Manufacturing

Blog Article

Navigating the World of Fasteners and Machining: Methods for Accuracy and Speed

In the elaborate realm of fasteners and machining, the mission for precision and speed is a perpetual difficulty that demands meticulous attention to detail and tactical planning. From understanding the diverse array of bolt kinds to picking ideal materials that can stand up to extensive demands, each step in the process plays a pivotal duty in attaining the preferred result.

Understanding Fastener Types

When picking fasteners for a project, comprehending the various types readily available is essential for making certain optimal performance and integrity. Bolts are utilized with nuts to hold products together, while screws are versatile fasteners that can be used with or without a nut, depending on the application. Washers are important for dispersing the lots of the fastener and avoiding damages to the product being fastened.

Choosing the Right Products

Understanding the significance of choosing the appropriate products is paramount in guaranteeing the ideal performance and reliability of the picked bolt kinds talked about formerly. When it comes to bolts and machining applications, the product option plays an important function in establishing the total toughness, resilience, rust resistance, and compatibility with the intended atmosphere. Various materials use differing homes that can substantially affect the efficiency of the fasteners.

Usual materials made use of for fasteners include steel, stainless steel, brass, aluminum, and titanium, each having its unique staminas and weaknesses. Steel is renowned for its high stamina and toughness, making it appropriate for a vast variety of applications. Picking the best product involves thinking about variables such as stamina requirements, ecological problems, and budget plan restraints to ensure the preferred efficiency and longevity of the fasteners.

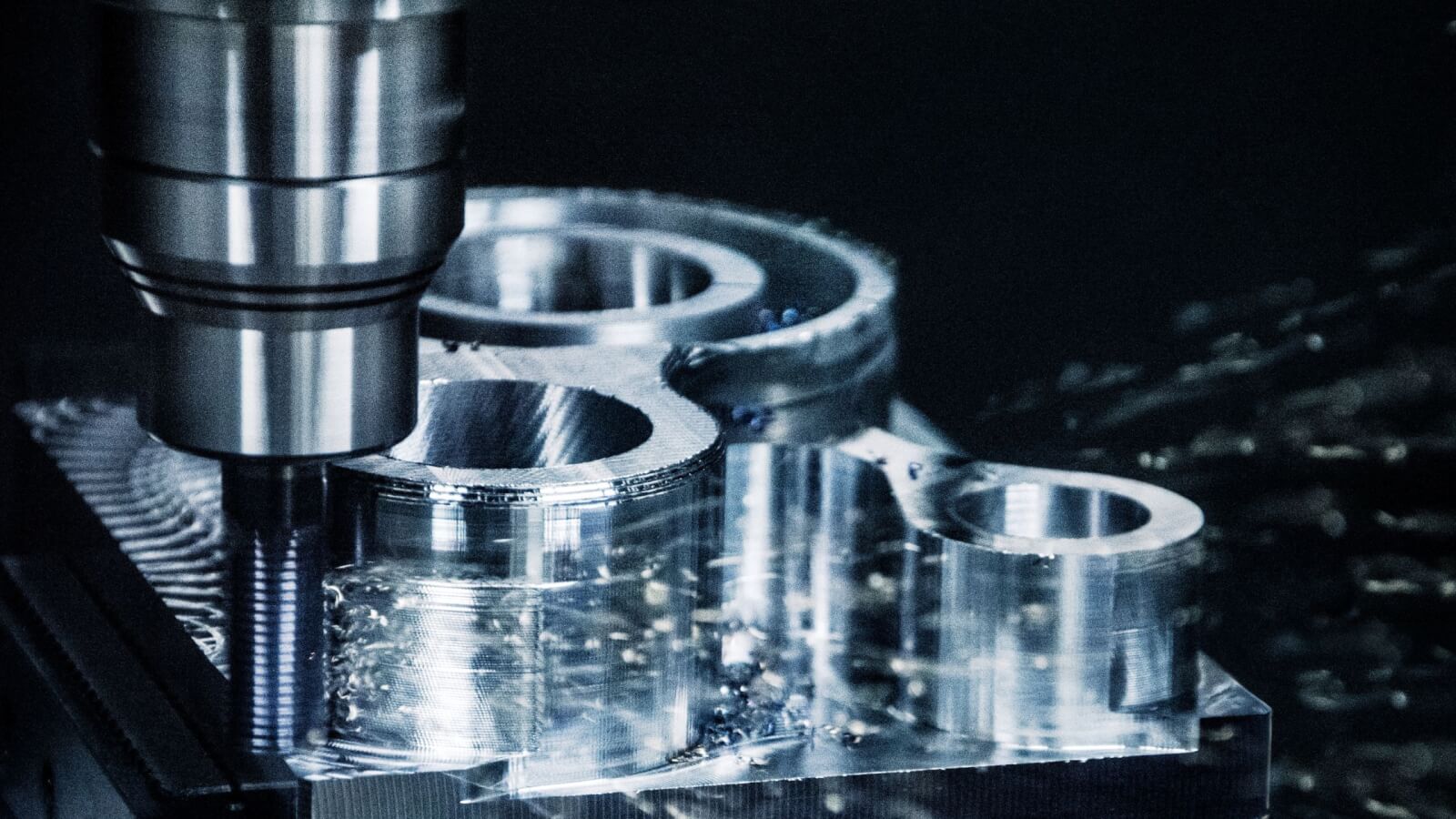

Accuracy Machining Techniques

Along with CNC machining, various other precision methods like grinding, transforming, milling, and drilling play crucial roles in fastener manufacturing. Grinding aids accomplish fine surface area finishes and tight dimensional resistances, while transforming is typically made use of to create cylindrical elements with exact diameters. Milling and drilling procedures are crucial for shaping and producing openings in bolts, guaranteeing they meet specific specifications and function properly.

Enhancing Rate and Efficiency

To optimize fastener production procedures, it is vital to streamline procedures and execute efficient methods that enhance accuracy machining strategies. One crucial method for see this boosting rate and performance is the implementation of lean manufacturing principles. By decreasing waste and concentrating on constant renovation, lean practices help enhance and get rid of traffic jams process. Additionally, purchasing automation modern technologies can considerably enhance manufacturing rate. Automated systems can take care of recurring jobs with accuracy and speed, enabling workers to focus on even more facility and value-added tasks. Embracing Just-In-Time (JIT) stock monitoring can also boost effectiveness by ensuring that the right products are readily available at the correct time, reducing excess inventory and try this site lowering preparations. Moreover, promoting a culture of cooperation and interaction among employee can improve total performance by promoting transparency, analytic, and advancement. By combining these strategies, makers can accomplish an equilibrium between rate and precision, inevitably enhancing their one-upmanship in the bolt industry.

Quality Control Steps

Executing strenuous top quality control steps is essential in ensuring the integrity and uniformity of fastener items in the manufacturing process. Fasteners and Machining. Quality control actions include various phases, starting from the option of review raw products to the final inspection of the ended up fasteners. This entails examining factors such as product composition, durability, and stamina to assure that the fasteners satisfy sector standards.

Normal calibration of equipment and machinery is essential to keep uniformity in production and make sure that bolts meet the necessary resistances. Executing stringent methods for identifying and resolving non-conformities or problems is crucial in preventing substandard products from going into the marketplace. By developing an extensive high quality control structure, suppliers can copyright the track record of their brand and supply bolts that meet the greatest requirements of efficiency and longevity.

Final Thought

In the elaborate realm of fasteners and machining, the quest for precision and speed is a perpetual challenge that demands precise interest to information and critical preparation. When it comes to bolts and machining applications, the product option plays a critical duty in determining the overall strength, longevity, deterioration resistance, and compatibility with the intended environment. Precision machining includes different sophisticated techniques that guarantee the tight tolerances and specifications required for bolts.In enhancement to CNC machining, various other accuracy methods like grinding, turning, milling, and drilling play essential duties in bolt production.To optimize bolt manufacturing procedures, it is vital to improve operations and apply effective techniques that enhance accuracy machining techniques.

Report this page